I've aligned hundreds of machines that looked perfect on paper.

Dial indicators showed 0.001" or less. We documented everything. Torqued the bolts to spec. Walked away thinking we nailed it.

Then three months later, the bearing failed.

Here's what I missed: thermal growth.

We aligned it cold. But when that centrifugal compressor hit operating temperature, the casing expanded. The bearing housing moved. The shaft centerline shifted 0.008" from where we set it.

That bearing never had a chance.

This article covers everything I wish someone had taught me about shaft misalignment—not just how to measure it, but why machines that look perfectly aligned still fail, and what to do about it.

Table of Contents

Part 1: Why Most Alignment Jobs Fail

Most techs think alignment is a one-time thing. Set it cold, document the readings, move on.

That's not wrong—but it's incomplete.

You need to account for what happens when the machine heats up. I've seen this pattern on steam turbines driving centrifugal compressors, synthesis gas compressors, boiler feed water pumps, and refrigeration compressors. Every time, the same story.

Cold alignment looks good. Hot alignment is a mess.

The Three Forces That Move Machines Out of Alignment

Even if you set perfect cold alignment, three forces are constantly working to pull your machine out of position:

1. Thermal growth Metal expands when it heats up. But it doesn't expand evenly. The top of a compressor casing heats up faster than the bottom. One end sees higher temperatures than the other. Bearing housings move vertically as they heat.

I've measured this on synthesis gas compressors in ammonia plant service. At startup, cold alignment was 0.002" within tolerance. After six hours at normal operating temperature, the driver had moved 0.012" vertically and 0.004" horizontally.

That's way outside tolerance.

2. Pipe strain Process piping pulls on pump and compressor nozzles. When pipes heat up or cool down, they expand or contract. That movement transfers directly to the machine casing.

I've measured pipe strain with dial indicators. Disconnect the suction and discharge piping, and take a reading. Reconnect the piping, take another reading. On one ammonia plant process pump, the shaft moved 0.015" laterally just from reconnecting the pipes.

That's not an alignment error. That's the piping fighting the machine.

3. Foundation settlement: Grout settles. Concrete cracks. Baseplates shift. These changes happen slowly—over months or years—but they're real.

I've seen machines that were perfectly aligned during commissioning end up 0.020" out after two years of operation. The alignment didn't drift. The foundation moved.

Why Cold Alignment Numbers Lie

Here's the fundamental problem: you're aligning the machine when it's cold and stationary. But you're trying to predict where it will be when it's hot and running.

Those are two completely different conditions.

A synthesis gas compressor at ambient temperature is not in the same position as that same compressor running at 400°F discharge temperature. The casing has expanded. The shaft has grown. The bearing housings have moved.

If you don't account for that movement, your "perfect" cold alignment becomes severe misalignment at operating temperature.

Part 2: What Misalignment Actually Does to Equipment

Misalignment doesn't just cause vibration. It initiates a cascade of failures that progresses through the entire machine train.

Here's what happens, step by step:

Stage 1: Bearing Overload (Weeks 1-4)

When shafts are misaligned, the coupling transmits bending forces to the bearing housings. Instead of supporting a purely radial load, the bearings now have to handle radial load plus an angular moment.

The load concentrates on the bearing edges instead of being distributed evenly across the bearing surface.

Oil film thickness drops at the edges where the load is highest. Friction increases. Temperature spikes. The oil starts breaking down at the hot spots.

You won't see this in vibration data yet. But it's already happening.

I've pulled bearings after just 30 days on a misaligned machine and seen clear evidence of edge loading—Babbitt wiped on one side while the other side looked brand new.

Stage 2: Seal Failure (Weeks 4-12)

Mechanical seals need the shaft to run true. Misalignment causes radial runout at the seal faces. The seal faces can't maintain consistent contact.

First symptom: weeping. A few drops per day.

Then the seal face starts running hot because it's not tracking properly. The secondary seal (O-rings) starts to degrade from heat.

Within weeks, you've got a full seal failure—leaking product, contaminating the bearing oil, creating a safety hazard.

I've seen seal failures within two weeks on severely misaligned ammonia circulation pumps. The seal would be fine during the first cold run. Then the machine would heat up, thermal growth would pull it out of alignment, and the seal would start leaking.

Stage 3: Coupling Damage (Months 2-6)

Flexible couplings can handle some misalignment—but not much. Most elastomeric couplings are designed for 0.5-1.0 degrees of angular misalignment and 0.010-0.020" of parallel offset.

Exceed those limits, and the coupling starts working against you instead of with you.

The elastomer generates heat as it flexes. High heat breaks down the polymer. The coupling gets progressively weaker. Eventually, it starts shedding chunks of rubber or cracking the metallic elements.

I've opened coupling guards on misaligned machines where the coupling was so hot I couldn't touch it—120°F surface temperature on what should be a 90-95°F ambient.

That heat isn't normal. That's the coupling trying to accommodate misalignment; it wasn't designed to handle it.

Stage 4: Bearing Failure (Months 3-12)

By this point, the bearing has been running with edge loading and elevated temperatures for months. The Babbitt has been plastically deforming. The oil has been degrading at the hot spots.

Then one day, you get the alarm.

Bearing temperature spikes. Vibration increases. You start seeing metal in the oil samples.

The bearing has failed.

Typical timeline I've seen:

Synthesis gas compressor: 3-6 months

High-speed ammonia refrigeration compressor (3,600+ RPM): 2-4 months

Boiler feed water pump: 4-8 months

Speed increaser gearbox (1,800 RPM): 6-12 months

Higher speeds accelerate the failure. But misalignment always wins eventually.

The Cost Cascade

Here's what a single misalignment-induced bearing failure actually costs:

Direct costs:

Bearing replacement: $5,000-$15,000

Seal replacement (because it failed too): $2,000-$8,000

Coupling replacement: $1,500-$5,000

Labor (24-48 hours minimum): $5,000-$10,000

Total direct cost: $13,500-$38,000

Indirect costs:

Lost production (48-72 hours typical): $50,000-$500,000 depending on process criticality

Emergency mobilization and overtime premiums: $10,000-$25,000

Collateral damage to connected equipment: varies widely

Total cost of one misalignment failure: $75,000-$550,000+

And if you don't fix the root cause—the misalignment itself—you'll be doing this again in 3-6 months.

I've seen plants spend $200,000+ per year on a single chronically misaligned compressor. New bearings every six months. Seals every three months. Couplings annually.

All because nobody accounted for thermal growth.

Part 3: The Diagnostic Framework—How to Actually Find Misalignment

You can't fix what you can't measure. Here's the complete diagnostic framework I use in the field.

Tool 1: Vibration Analysis (FFT Spectrum)

If you've got a vibration analyzer, the FFT spectrum gives you clear signatures for different types of misalignment.

Angular misalignment signature:

High 1X axial vibration (0.3-0.5 in/sec, where normal is 0.1-0.15 in/sec)

2X axial present but lower amplitude than 1X

Measured at the bearing housings closest to the coupling

Parallel misalignment signature:

High 2X radial vibration (often exceeds 1X amplitude)

1X radial present but secondary

Sometimes, a 3X harmonic is visible in severe cases

Combined misalignment (most common):

Both 1X axial and 2X radial elevated

Multiple harmonics visible (1X, 2X, 3X)

The phase relationship shows a 180-degree shift across the coupling

I've diagnosed hundreds of misalignment cases using FFT. The 2X radial peak is almost always the first indicator I see.

But here's the catch: if your running speed's second harmonic (2X) happens to land near a system's natural frequency, the vibration gets amplified significantly. Conversely, if 2X is far from any resonance, the vibration might be damped and harder to detect.

Always consider system dynamics when interpreting spectra.

Tool 2: Phase Analysis

Phase measurement confirms what the FFT spectrum suggests.

Measure radial vibration phase on the driver and driven equipment at the bearing closest to the coupling. If you're seeing a 180-degree phase difference, that's misalignment.

What that means physically: the two shafts are moving in opposition. The coupling is forcing them into positions they don't want to be in, creating reaction forces that oppose each other.

I don't always have access to phase measurement capability in the field. But when I do, and I see that 180-degree shift, I know exactly what I'm dealing with—no ambiguity.

Tool 3: Shaft Orbit Analysis

This is more advanced, but incredibly powerful when available.

A shaft orbit plot shows the actual path the shaft centerline traces as it rotates. A well-aligned, balanced shaft traces a small circular or slightly elliptical orbit.

A misaligned shaft—especially with combined angular and parallel misalignment—traces a distorted path. Often it's a figure-8 pattern, sometimes elongated, sometimes compressed, depending on the severity and type of misalignment.

I've used orbit analysis on critical compressor trains. When you see that figure-8 orbit, there's no question. The machine is misaligned.

Tool 4: Temperature Monitoring

The simplest diagnostic tool: your hand.

After you shut down a machine, immediately feel the bearing housings and coupling guard.

If one bearing is noticeably hotter than the other, you've probably got misalignment creating uneven loading. If the coupling guard is too hot to touch (over 110-120°F on a machine that's been running in 80-90°F ambient), the coupling is working too hard.

This isn't precise. But I've caught misalignment issues this way more times than I can count—especially on machines where I didn't have vibration monitoring installed.

Temperature is your early warning system. By the time you see elevated vibration, the damage process is already advanced. High temperature shows up first.

Tool 5: Oil Analysis

Bearing oil analysis can reveal misalignment before you see it in vibration or temperature.

Look for:

Increasing wear metals (iron, copper) over successive samples

Particles that are larger and more angular (indicating rubbing wear)

Decreasing oil viscosity from thermal breakdown

I've seen oil samples come back with 3-4X normal iron content months before the bearing temperature alarm went off. That's your advance warning.

If you're trending oil analysis and you see wear metals climbing steadily, check alignment—even if vibration looks normal.

Part 4: The Right Way to Handle Thermal Growth

Here's what I do now on critical machines where thermal growth is a factor:

Step 1: Get the Thermal Growth Data

First, check the OEM manual. Most manufacturers provide thermal growth tables that tell you exactly how much vertical and horizontal movement to expect at various operating temperatures.

These tables are usually based on FEA analysis or actual measurements during factory testing. They're reliable.

If you don't have OEM data, you can estimate using basic thermal expansion calculations:

ΔL = α × L × ΔT

Where:

ΔL = change in length

α = coefficient of thermal expansion (typically 6.5 × 10⁻⁶ in/in/°F for carbon steel)

L = original length

ΔT = temperature change

Example: A compressor with a 48" tall casing going from 70°F to 400°F:

ΔL = (6.5 × 10⁻⁶) × 48 × (400-70) = 0.0103" ≈ 0.010" vertical growth

That's just the casing. You also need to account for baseplate growth, foundation effects, and bearing housing expansion.

OEM data is always better than calculations. But if you don't have it, at least calculate an estimate.

Step 2: Set Cold Alignment to Compensate

If the driven equipment is going to grow 0.010" vertically at operating temperature, you need to set it 0.010" low when it's cold.

This is called "offset alignment" or "pre-compensation."

Here's the typical process:

Calculate or obtain thermal growth values (vertical and horizontal)

Set the cold alignment to the inverse of the expected growth

When the machine heats up, it grows into the correct position

This feels wrong the first time you do it. Your laser alignment system is showing red—the machine is "out of tolerance." But you're compensating for thermal growth, so that's correct.

I've had supervisors question me on this. "Why are you setting it low?" Because when it's hot, it'll be right where it needs to be.

Document this clearly. Write on the alignment report: "Cold offset: -0.010" vertical to compensate for +0.010" thermal growth at operating temperature."

Step 3: Verify With a Hot Alignment Check

On critical machines—especially in LNG, refinery, or high-temperature service—I always do a hot alignment check after the first full-temperature run.

This requires laser alignment tools that can measure running machinery. Not all systems can do this, but the high-end ones can.

Procedure:

Let the machine reach stable operating temperature (typically 4-6 hours)

Take running alignment readings with the laser system

Compare hot readings to target alignment

If hot alignment is within tolerance, the cold offset was correct

If not, adjust the cold offset for the next alignment and document the actual hot growth observed

You can't do this on every machine. But on a $5M compressor train, it's absolutely worth the time and cost to verify you got it right.

I've found discrepancies between OEM-predicted growth and actual measured growth of 20-30% on several machines. Field conditions don't always match factory test conditions.

Hot checks give you real data.

Step 4: Account for Multiple Operating Conditions

Some machines don't run at one temperature. They cycle. Or they have multiple operating modes.

Example: A compressor that runs at 250°F during normal operation but can see 350°F during upset conditions.

You have to choose your alignment target. Options:

Option A: Align for normal operating temperature (250°F)

The machine runs best 90% of the time

Accepts some misalignment during 350°F upsets

Usually, the right choice for process stability

Option B: Align for worst-case temperature (350°F)

The machine is slightly misaligned during normal operation

Protects against damage during upsets

Used when upsets are frequent or severe

Option C: Align for an intermediate temperature

Compromise that minimizes misalignment across the range

Typical approach when the machine sees wide temperature swings regularly

There's no universal right answer. It depends on how the machine operates.

I usually align for the condition that the machine spends the most time in. If it runs at 250°F for 95% of its life and only sees 350°F during startup or emergency conditions, I align for 250°F.

Part 5: Handling Pipe Strain

Thermal growth isn't the only force that moves machines. Pipe strain is just as destructive—and harder to predict.

What Pipe Strain Actually Is

Pipe strain is the force exerted on equipment nozzles by connected piping. It happens when:

Piping is not properly supported or anchored

Thermal expansion of hot piping pulls on the equipment

Piping was forced into position during installation

Expansion loops or flex joints are undersized or improperly located

The piping system essentially treats your pump or compressor as a structural support. That's not what it's designed for.

How to Measure Pipe Strain

Here's my field procedure:

Step 1: With piping connected, measure the shaft position with dial indicators (or laser) at the coupling

Step 2: Disconnect suction and discharge piping at the nearest flanges

Step 3: Measure the shaft position again

Step 4: Calculate the difference

If the shaft moves more than 0.002" in any direction when you disconnect the piping, you have excessive pipe strain.

I've measured movements of 0.010-0.020" on poorly supported piping systems. That's severe.

How to Fix Pipe Strain

The proper fix is to adjust the piping supports until the piping self-supports without loading the equipment nozzles.

Process:

Disconnect piping

Adjust pipe hanger locations, spring can settings, or support elevations

Reconnect piping

Verify shaft movement is under 0.002"

If still excessive, repeat adjustments

This is tedious work. Sometimes it requires cutting and re-welding pipe supports. Sometimes it means adding additional hangers or changing spring can settings.

But it's necessary.

API 610 (centrifugal pumps) and API 617 (compressors) both specify maximum allowable nozzle loads and moments. If your piping exceeds those limits, you're going to have reliability problems—no matter how good your alignment is.

The Thermal Growth Pipe Strain Interaction

Here's where it gets complicated: piping experiences thermal growth, too.

When process piping heats up, it expands. That expansion changes the forces on the equipment nozzles. So pipe strain isn't constant—it varies with operating temperature.

I've seen cases where cold pipe strain was minimal (0.001" movement), but hot pipe strain was severe (0.015" movement) because the hot piping was pulling the pump casing laterally.

If you're dealing with high-temperature service (250°F+), you need to consider both equipment thermal growth AND piping thermal expansion when setting your cold alignment targets.

This is why LNG and gas processing applications are so challenging. You're trying to predict the interaction between multiple thermal expansion effects happening simultaneously.

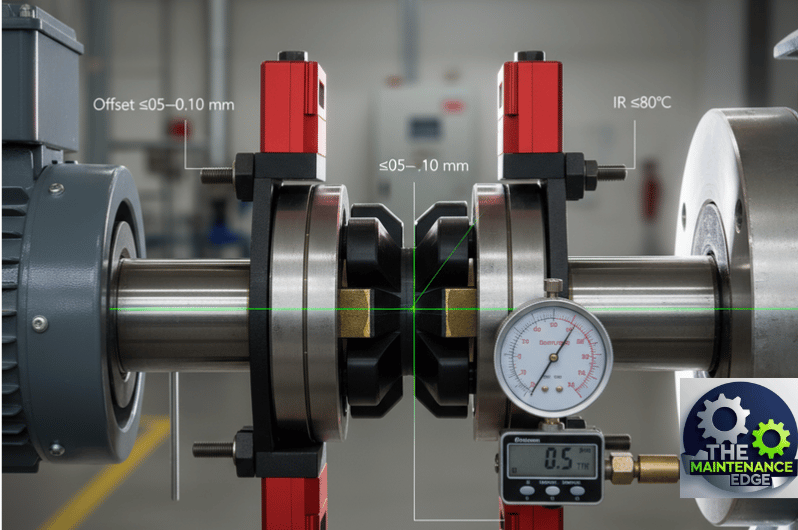

Part 6: My Alignment Standards and Tolerances

Here's what I use for final alignment tolerances on coupled rotating equipment:

For General Industrial Service (0-250°F operating temp):

Parallel offset: 0.002" or less. Angular offset: 0.001" per inch of spacer length or less

Example: 10" spacer coupling = 0.010" maximum angular offset between shaft ends

For Critical or High-Speed Service (Above 3600 RPM or Above 250°F):

Parallel offset: 0.001" or less, Angular offset: 0.0005" per inch of spacer length or less

These are tight tolerances. Some people say you can get away with more. Maybe. But I've seen too many bearing and seal failures on machines that were "close enough."

If I can get parallel within 0.001" and angular within 0.0005" per inch, I do. Tighter is always better for equipment life.

Alignment Repeatability Check

I also verify alignment repeatability. After setting the final position, I:

Break the feet loose

Re-torque

Recheck alignment

If my readings change by more than 0.0005", I've got a soft foot issue or base distortion problem that needs to be addressed before I accept the alignment.

Repeatability matters. If you can't get consistent readings, you don't have a stable alignment.

The 180-Degree Rule

When aligning coupled equipment, you need to decide which machine to use as your reference (the fixed, stationary anchor) and which machine to move.

General rule: The more rigid the machine is, the more it is your reference. The less rigid machine gets moved.

Most of the time:

Compressor or pump (driven equipment) = rigid anchor

Motor or turbine (driver) = movable machine

But not always. A small pump might be less rigid than a large motor. Use judgment based on actual equipment mass and baseplate stiffness.

Part 7: Real-World Case Studies From the Field

Here are three actual misalignment cases I've dealt with, showing different failure modes and solutions:

Case Study 1: Ammonia Refrigerant Compressor—Thermal Growth Failure

Equipment: Steam turbine driver + centrifugal ammonia refrigeration compressor. Service: Propane refrigerant compression, -20°F suction, 350°F discharge. Problem: Repeated compressor thrust bearing failures every 4-6 months

Initial Investigation:

Cold alignment was within OEM specs (0.002" parallel, 0.0008" per inch angular)

Vibration during operation was acceptable (1X = 0.12 in/sec)

But the thrust bearing temperature was running 20°F higher than design

Root Cause: I requested a running (hot) alignment check. Results showed the compressor had moved 0.014" vertically upward at operating temperature—far more than the 0.008" predicted by OEM thermal growth tables.

The actual thermal growth was 75% higher than predicted because:

Casing was hotter than design (400°F actual vs. 350°F design)

Foundation grout had degraded, reducing heat sink capacity

The ambient temperature was higher than the factory test conditions

Solution:

Re-aligned cold to -0.014" vertical offset (compensating for measured hot growth)

Added bearing temperature monitoring with tighter alarm limits

Scheduled hot alignment check after every major shutdown

Result: Compressor ran for 3+ years without bearing failure after correction. Thrust bearing temperature dropped to design values.

Case Study 2: Gas Processing Boiler Feed Water Pump—Pipe Strain Induced Misalignment

Equipment: Multi-stage boiler feed water pump, 1200 HP motor driver. Service: 650 GPM, 400°F, 600 PSIG discharge. Problem: Mechanical seal failure every 6-8 weeks, always on the pump side

Initial Investigation:

Alignment was checked and "corrected" three times in six months

Each time, cold alignment readings were within tolerance

But the seal kept failing at approximately the same interval

Discovery: I performed a pipe strain test. With piping disconnected, the pump shaft moved 0.018" laterally (toward the discharge side). When piping was reconnected, the shaft moved back.

The hot discharge piping was pulling the pump casing sideways. Every thermal cycle stressed the seal faces differently, preventing them from seating properly.

Solution:

Added two pipe support hangers on the discharge line between the pump and the first elbow

Adjusted spring can settings on existing supports

Re-checked pipe strain: reduced to 0.001" movement

Re-aligned the pump with the piping connected

Result: Seal life increased from 6-8 weeks to 18+ months. Problem solved.

Case Study 3: Compressor Speed Increaser Gearbox—Foundation Settlement Over Time

Equipment: Speed increaser gearbox, 3000 HP, driving a synthesis gas compressor. Service: Compressor drive train, continuous operation. Problem: Gradually increasing vibration over an 18-month period finally triggered the alarm

Initial Investigation:

Vibration was primarily 2X radial (misalignment signature)

Bearing temperatures were slightly elevated, but not alarming

The machine had been running fine for the first two years after commissioning

Discovery: Current alignment was 0.016" parallel offset—way outside tolerance. But commissioning records showed it had been aligned to 0.001" initially.

The baseplate had settled over time. Grout had developed voids underneath. The entire gearbox had dropped approximately 0.015" relative to its original position.

Solution:

Performed complete grout remediation (removed old grout, cleaned surfaces, re-grouted)

Re-leveled baseplate

Re-aligned to 0.001" parallel, 0.0005"/inch angular

Installed dial indicators permanently to monitor for future settlement

Result: Vibration dropped from 0.35 in/sec to 0.08 in/sec. Gearbox continues to run reliably three years later with no further settlement issues.

Part 8: The Alignment Checklist I Use on Every Job

Here's my complete pre-alignment and post-alignment checklist. I don't skip steps.

Pre-Alignment Checklist:

☐ Verify machine is de-energized and locked out ☐ Check soft foot (all four feet, 0.002" maximum gap) ☐ Verify baseplate is level and grouted solidly ☐ Check foundation for cracks or voids ☐ Measure pipe strain (disconnect/reconnect test) ☐ Verify coupling is in good condition (no cracks, wear, or damage) ☐ Obtain OEM thermal growth data or calculate expected growth ☐ Review operating temperature and determine alignment target (cold offset if needed) ☐ Check for any mechanical interferences (piping, conduit, etc. that might prevent movement)

During Alignment:

☐ Use proper bolt torque sequence (cross-pattern, opposite corners) ☐ Verify shim stack integrity (3-5 shims maximum, stainless steel, no gaps) ☐ Check alignment repeatability (should repeat within 0.0005") ☐ Re-check soft foot after final torque ☐ Document cold alignment readings ☐ Photograph final shim configuration ☐ Mark both machines with reference points for future checks

Post-Alignment Verification:

☐ Verify coupling rotates freely by hand (no binding) ☐ Check bearing clearances (should be within OEM specs) ☐ Bump motor and verify rotation direction ☐ Monitor first startup closely (vibration, temperature, noise) ☐ If possible, perform hot alignment check after reaching operating temperature ☐ Update maintenance records with alignment data and thermal growth observations ☐ Set up trending for vibration and bearing temperature

Part 9: When to Re-Align Equipment

Alignment isn't "one and done." Here's when I schedule re-alignment:

After Any Major Work:

Bearing replacement

Seal replacement

Coupling replacement

Baseplate work or grouting

Foundation repairs

Piping modifications near the machine

Any time you disturb the machine or its mounting, verify alignment before you put it back in service.

Scheduled Preventive Checks:

Critical machines (compressors, high-speed pumps): Every 12-18 months. Standard machines: Every 24-36 months. Low-criticality or slow-speed equipment: Every 48-60 months or as-needed based on condition

These are guidelines. Adjust based on your specific operating conditions and failure history.

Condition-Based Triggers:

Re-align immediately if you see:

Vibration increase of 50% or more over baseline

Bearing temperature increase of 15-20°F over baseline

Repeated seal failures (more than one in a 12-month period)

Coupling showing signs of distress (heat, wear, cracking)

Any evidence of pipe strain or foundation settlement

Don't wait for a scheduled PM. If the machine is telling you something's wrong, check alignment.

Part 10: What I Wish Someone Had Told Me

When I was younger, I thought precision alignment was about getting perfect dial indicator readings during a shutdown. Set it to 0.001", document it, done.

I didn't understand that alignment is dynamic.

The machine moves when it heats up. It moves when process loads change. It moves when pipes expand. It moves when the foundation settles.

I aligned machines that failed within months because I didn't account for any of that. I chased vibration problems that were really alignment problems. I replaced bearings and seals that would have lasted years if the alignment had been right.

Here's what I know now:

Alignment isn't a number. It's a prediction.

You're not just measuring where the shafts are right now. You're trying to predict where they'll be when the machine is running at temperature, under load, with hot piping connected, six months from now.

That requires understanding thermal growth, pipe strain, foundation stability, and how all of those factors interact.

It requires going beyond the manual. OEM alignment specs are starting points, not final answers. You need to verify them with field measurements and hot checks.

It requires proper documentation. If you don't record what the machine is doing at different temperatures and operating conditions, you're starting from scratch every time you come back to it.

Most importantly, cold alignment numbers tell you where the machine is during a shutdown. Hot alignment numbers tell you where it is when it's actually running.

Big difference.

How to Use This Guide

This is a reference document. You don't need to read it cover-to-cover every time you do an alignment job.

Instead, use it like this:

Before your next alignment:

Review Part 4 (thermal growth) and Part 5 (pipe strain)

Use the checklist in Part 8

Reference the tolerance standards in Part 6

When troubleshooting a vibration or bearing problem:

Review the diagnostic framework in Part 3

Compare your symptoms to the case studies in Part 7

Check the failure timeline in Part 2 to understand what stage you're seeing

When training someone new:

Start with Part 1 (why alignment fails)

Work through Part 2 (failure progression)

Teach them the checklist in Part 8 before they touch a machine

When you see something unusual in the field:

Come back to this guide

See if one of the case studies matches your situation

Use it to build your own case study library

This guide is based on 29 years of field experience—mistakes I've made, failures I've seen, and solutions that actually worked.

Use it. Adapt it to your equipment and operating conditions. Build on it.

And if you find something that works better than what's in here, document it and share it with your team.

Next Steps: Building Your Alignment Skills

If you're serious about mastering alignment, here's what to focus on:

1. Get good at soft foot checks. This is foundational. If you can't eliminate soft foot, your alignment will never be stable. Practice until you can consistently get all four feet within 0.002".

2. Learn to interpret vibration spectra. You don't need to be a vibration expert. But you should be able to recognize the 1X, 2X, and 3X patterns that indicate misalignment. Take a basic vibration analysis course if your company offers it.

3. Measure thermal growth on your critical machines. Pick one or two critical machines and actually measure how much they move from cold to hot. Compare your measurements to OEM predictions. Build your own thermal growth database.

4. Document everything. Keep alignment records. Not just final numbers, but also thermal growth observations, pipe strain measurements, and what operating conditions were present. Over time, you'll build a knowledge base that makes every subsequent alignment faster and more accurate.

5. Do hot checks when possible. Any time you have access to laser alignment tools that can measure running equipment, use them. Hot alignment data is invaluable.

What's your biggest alignment challenge right now? Thermal growth? Pipe strain? Vibration that won't go away, no matter how many times you re-align?

Drop a comment and let's talk through it.

I look forward to seeing you next week.

Additional Resources

If you want to go deeper on alignment topics, here are the industry standards and references I use:

Industry Standards:

API 610: Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries

API 617: Axial and Centrifugal Compressors and Expander-compressors

ANSI/ASA S2.75-2017: Guidance for Measurement of Shock and Vibration Applied to Rotating Machines

ISO 20816-1: Mechanical Vibration - Measurement and Evaluation of Machine Vibration

Recommended Training:

Precision shaft alignment courses (hands-on with laser alignment tools)

Vibration analysis Level I certification (ISO 18436 or equivalent)

Machinery reliability workshops focused on rotating equipment

Tools Worth Investing In:

Quality laser alignment system (Fixturlaser, Easy-Laser, or equivalent)

Vibration analyzer with FFT capability

Precision dial indicators (0.0001" resolution)

Digital inclinometer for baseplate leveling

Infrared thermometer for quick bearing temperature checks